Products

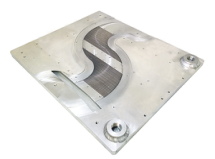

LCP serves as a highly effective heat sink for power modules like IGBT,GTO and CPU, compare to air cooling heat sink it improve the installation density, reliability and reduce the energy consuption of the heat dissipation in the same time Through finite element thermal analysis method, it make the liquid cooling heat sink faster, more accurcy and reduce the test number, which guarantee the companent reliability in their rate condition and lifecycle

Products Profile

Specification

| Experiment Item | Standard | Routine test | Type test | Capability of test |

| Apperance | / | √ | √ | Yes |

| Product Size | / | √ | √ | Yes |

| Partial discharge | IEC 60270:2000 | √ | √ | Yes |

| Pressure test | / | √ | √ | Yes |

| weigh measurement | / | √ | √ | Yes |

| inductance measurement | / | √ | Yes | |

| current rated test | IEC60068-2-14-1984 | √ | Yes | |

| cyclic damp heat test | IEC 60068-2-30:2005 | √ | Out sourcing | |

| temperature cycle test | IEC60068-2-14 | √ | Yes | |

| salt spray test | IEC60068-2-11:1999 | √ | Yes | |

| viberation and impluse test | IEC61373 Class One, Standard B | √ | Out sourcing | |

| Creepage distance detection | / | √ | Yes | |

| Coating Thinkness test | / | √ | Yes | |

| Fire and smoke tests | NFF16-101/16-102 | √ | Out sourcing |

Testing Capabilities

| Heat resistance test of radiator. | Temperature rise & flow resistance test platform for heat sink |

| Water immersion ultrasound C scan. | |

| Three coordinate measurement | CMM (Coordinate Measuring Machine) |

| Air leak test | Air leakage tester |

| Roughness test | Roughness tester |

| Digital display hardness | Digital Hardness tester |

| X ray thickness | X-ray thickness gauge |

| Conductivity detection. | Conductivity tester |

| Metallographic test | Metallurgical microscope |

Industrial & Solution

Power Transmission & Distribution |

|

Rail Transit |

|

Telecommunicate |

|

Electric Vehicle |

|

COPYRIGHT (©) vtle All Rights ReservedSitemapPrivacy Policy